FAQ Chain Slings

On this page you will find frequently asked questions from our customers about chain slings. If you are concerned about a question that is not answered here, please do not hesitate to ask us. We will be happy to answer them by mail.

Your Questions:

- What are chain slings?

- What are sling shortening hooks?

- What grades does Dolezych have in its product range?

- Which chain systems can be supplied?

- What is the difference between the individual grades?

- How do I identify the different grades?

- What is the tilt angle and how is it measured?

- What is the spread angle?

- What is the working length of a chain sling?

- Why must the hooks always point outwards?

- Can I also use a multi-leg chain in a single leg?

- What documents will I receive when I order a chain sling from Dolezych?

- How is the chain sling labelled correctly?

- What information can I find on the load capacity tag of the chain?

- What information can I find on the inspection plate?

- What is the lifting capacity of the chain sling if the load capacity tag is lost?

- How often must I have my chain slings and associated components checked?

- When is a chain sling out of service?

- May chain slings be used in pickling plants and hot-dip galvanizing plants?

- At what temperatures may the chain slings be used?

- Which regulations are fundamental for the use of chain slings?

Our Answers:

What are chain slings?

Grade 8 and grade 10 chain slings are among the most important slings. They are used in a wide variety of applications to lift heavy loads or goods (e.g. on construction sites or in industry).

What are sling shortening hooks?

Sling shortening hooks are always used in connection with chain suspensions. The variably usable shortening hooks with safety device save components and shorten sling and lashing chains directly in the working area.

What grades does Dolezych have in its product range?

Chain slings are available from Dolezych in grades 6, 8, 10 and 12.

- Grade 6: DoKett – Stainless steel chain slings

- Grade 8: DoKett – Chain slings

- Grade 10: DoKettPlus – Chain slings, DoComfort – chain slings

- Grade 12: DoComfortMax – Chain slings

Other grades on request.

Which chain systems can be supplied?

- Modular system

- Mounting with chain connecting links (grade 6, 8, 10)

- Mounting in clevis system (grade 6, 10, 12)

- Welding system

Please request chain suspensions for special applications from your Dolezych team!

What is the difference between the individual grades?

The difference between the individual grades of chain slings is that the load capacity increases with increasing grade while the material thickness remains the same.

How do I identify the different grades?

The grade of a chain, as well as its components (hooks, connecting links, shorteners, etc.) can be recognized by the grade labels 8, 10 and 12.

What is the tilt angle and how is it measured?

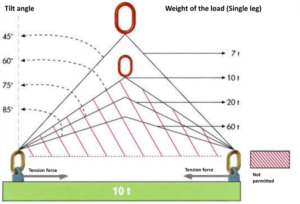

The tilt angle is determined by the degrees between an imaginary vertical line and the chain itself. The load carrying capacity of a chain sling changes depending on the respective tilt angle of a suspended load: the greater the tilt angle, the lower the load capacity. Tilt angles exceeding 60° are not permitted! If different tilt angles occur with multiple leg chain slings (asymmetrical load distribution), only the load capacity of the leg with the largest tilt angle may be used as a basis. In individual cases, shortening hooks and compensating rockers may be helpful.

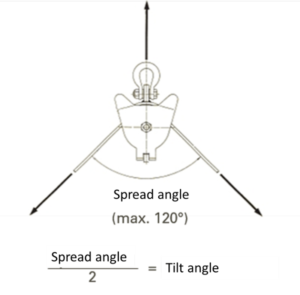

What is the spread angle?

In contrast to the tilt angle, the spread angle measures the angle between two chain legs (maximum 120°).

What is the working length of a chain sling?

The working length L describes the length of a chain sling plus its fitting parts, as shown in the following diagram.

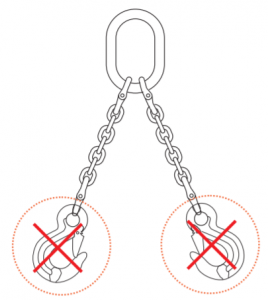

Why must the hooks always point outwards?

The hook openings must always point outwards to prevent the load from being unhooked unintentionally.

Can I also use a multi-leg chain in a single leg?

Yes, the unloaded chain legs are hung back into the suspension link/set. In this case the permissible WLL is reduced to that of a single leg chain.

What documents will I receive when I order a chain sling from Dolezych?

Certificate of Compliance DIN EN 10204-2.1 and Declaration of Conformity are automatically included in the scope of delivery. A chain file card is issued in the course of our annual UVV inspection.

Further documents on request.

How is the chain sling labelled correctly?

A chain sling is always identified by a load capacity label and by Dolezych additionally with an UVV inspection plate.

What information can I find on the load capacity tag of the chain?

- Load capacity in t for

- 1-leg smaller than tilt angle 0°

- 2-/3-/4-legs at a tilt angle of 0°-45° / 45° – 60°

- nominal thickness of the chain in mm

- date of manufacture (month/year)

- Manufacturer’s mark of Dolezych (DD)

- CE-sign

What information can I find on the inspection plate?

Date of the next UVV inspection (month/year)

What is the lifting capacity of the chain sling if the load capacity tag is lost?

In this case, the sling chain is downgraded to grade 2 (DIN 685) and must be inspected by an expert in due time. Do not hesitate to contact us by mail. We are happy to answer your questions.

How often must I have my chain slings and associated components checked?

Basically, a chain sling must be inspected by a qualified person before it is used for the first time. In addition, DGUV 100-500, item 2.8 prescribes regular inspections at intervals of no more than one year by an expert for lifting equipment. Depending on the conditions of use inspections may also be required at shorter intervals than one year. This applies, for example, in the case of frequent use, increased wear, corrosion or heat effects or if increased susceptibility to failure is to be expected. Round steel link chains used as slings must be subjected to a special inspection for the absence of cracks at intervals of a maximum of three years (or a maximum of two years in Austria). We carry out this crack test with an electromagnetic crack testing device in our laboratory or with our test trolley at your site.

You are interested in our inspection service? Do not hesitate to contact us by mail.

When is a chain sling out of service?

- Cracks or deformations of a chain link

- Decrease of the averaged link thickness at any point by more than 10% of the nominal thickness

- Elongation of the outer nominal dimension L by more than 3% (or an inner elongation of 5%)

- Expansion of the hook mouth by more than 10% or other deformations

- Wear of the hook bottom by more than 5%

- Wear of the suspension and end links (material thickness in mm) by more than 10%

- Missing or illegible identification tag (reduce load capacity according to quality class 2)

- Discoloration due to heat influence

May chain slings be used in pickling plants and hot-dip galvanizing plants?

No, the use is not permitted according to the BG rules and DIN standards.

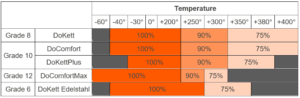

At what temperatures may the chain slings be used?

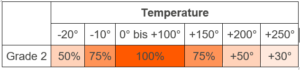

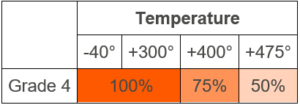

The following table shows the load carrying capacity per grade in relation to temperature.

Which regulations are fundamental for the use of chain slings?

The applicable regulations and technical rules for chain slings can be read in detail in the following works:

- Chains slings grade 8 / 10 / 12 DIN EN 818-2 / DIN EN 818-4 / PAS 1061

- Chain slings grade 6 (stainless steel) similar to DIN 5688-1

- DIN 685 Part 5 Tested round steel chains, manual

- DIN EN 818-6 Chain slings, Instructions for use and maintenance

- DGUV 109-004 Safety regulations for round steel chains as slings in hot-dip galvanizing plants

- DGUV 100-500, section 2.8 Load suspension devices in hoist operation

- DGUV 209-013 Safety training letter for security guards

- 2006-42-EC-Directive for machines and their supplements

- DIN EN 1677-1-4 Components for slings – Safety

Special regulations beyond this must be observed, e.g. for the transport of dangerous goods. For American Standards, please see ASME B30.9.