FAQ Tiedown Straps

On this page you will find frequently asked questions from our customers about tiedown straps. If you are concerned about a question that is not answered here, please do not hesitate to ask us. We will be happy to answer them by mail.

Your Questions:

- What actually is load securing?

- Are you allowed to lift anything with tie downs?

- Is there an expiration date for tie downs?

- Is the driver also responsible for securing the load?

- Can I shorten the webbing myself?

- Can I freely choose the webbing color of my tie down?

- Do the different colors of tie downs have anything to do with the pretensioning force?

- What do the stripes on the webbing of a tie down mean?

- What is the compatibility of PES webbing with gasoline, diesel or sharpie?

- Does the Doleco USA item number say anything about the length of the article?

- When do tie downs have to be removed from service?

Our Answers:

What actually is load securing?

Definition: Load securing refers to the professional and effective securing of loads or goods in transit using, for example, tie downs to counteract the physical forces that occur during transport.

Are you allowed to lift anything with tie downs?

No, tie downs must not be used for lifting because they are not designed for lifting. Tie downs are used exclusively for securing loads. That’s why every tie down label has the words, “Don’t lift, for tiedown use only!” (see illustration) Suitable products for lifting are, for example, web slings, round slings, loop straps, rope slings and lifting sling chains.

Is there an expiration date for tie downs?

No, there is no expiration date for tie downs, nor for round slings or loop straps. If they are stored and protected from the weather and UV exposure, and possibly even unused, you can use them for an indefinite period of time.

However to ensure that no harm occurs due to a defective strap during the next tiedown operation, all products should be visually inspected before each use. In addition, all of your load securing equipment should be inspected by an expert at least once a year.

Is the driver also responsible for securing the load?

Answer: Yes, even as a driver you are responsible for proper load securing in your vehicle. The only exception is if the vehicle was sealed by the consignor or customs prior to acceptance.

Can I shorten the webbing myself?

In principle, independent shortening of the webbing is not prohibited. However, we do not recommend it for the following reason: In our company, the webbing is cut and heat sealed. In this way, no threads are exposed, which could sooner or later lead to the unraveling of the webbing. In addition, if the webbing is not cut straight and sealed it makes it more difficult to thread it into the ratchet.

Our tip: If you still want to shorten the webbing yourself, you can seal the interface with a heat source.

Can I freely choose the webbing color of my tie down?

This is certainly possible for tie downs. The color of tie downs is not standardized, so you can freely choose the strap color when ordering. However, the following standard colors have been established at Doleco USA:

| Width: in mm | Break. Strength Cap.: | Type: | Color*: | Part No.: | Weight: |

| 1″ 25 | 4,500 lbs/2,045 kg | Nylon, 100 Yard roll | Blue | 5890 0001 | 0,09 lbs/0,04 kg |

| 2″ 50 | 6,000 lbs/2,727 kg | Polyester, Bulk Webbing | Yellow | 5890 0002 | 0,22 lbs/0,1 kg |

| 2″ 50 | 6,000 lbs/2,727 kg | Polyester, Bulk Webbing | Grey | 5890 0003 | 0,22 lbs/0,1 kg |

| 2″ 50 | 6,000 lbs/2,727 kg | Polyester, Bulk Webbing | Blue | 5890 0004 | 0,22 lbs/0,1 kg |

| 2″ 50 | 12,000 lbs/5,454 kg | Polyester, Latex Treated, Bulk Webbing | Yellow | 5890 0005 | 0,43 lbs/0,2 kg |

| 3″ 75 | 18,000 lbs/8,181 kg | Polyester, Latex Treated, Bulk Webbing | Yellow | 5890 0006 | 0,97 lbs/0,44 kg |

| 4″ 100 | 20,000 lbs/9,090 kg | Polyester, Latex Treated, Bulk Webbing | Yellow | 5890 0007 | 1,48 lbs/0,67 kg |

However, this is different for loop straps, round slings and web slings. These products have a specific color depending on the load capacity, which must not be changed.

Do the different colors of tie downs have anything to do with the pretensioning force?

No, not fundamentally. We have internally determined colors which we use as standard for certain tie downs. However, special designs are possible upon customer request. The strap color is freely selectable.

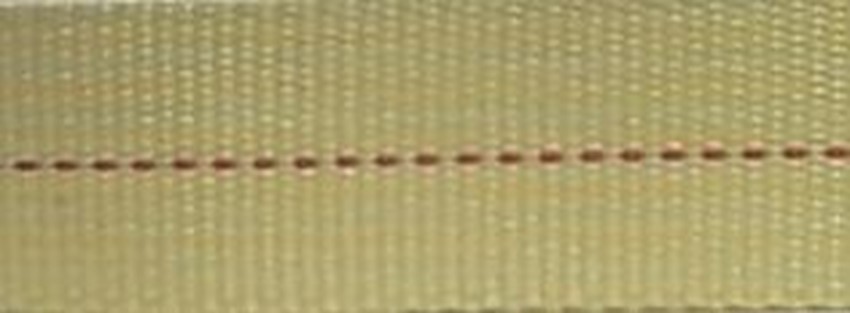

What do the stripes on the webbing of a tie down mean?

On flatbed tiedowns, a single stripe indicated a webbing of 5,000 lbs. per inch. A double line stripe indicates 6,000 lbs. per inch.

What is the compatibility of PES webbing with gasoline, diesel or sharpie?

Contact with diesel fuel and premium gasoline may result in minimal loss of color pigments. However, the strength of the belt itself is not affected. Marking with a sharpie also does not change the strength of the belt.

Does the Doleco USA item number say anything about the length of the article?

Yes and no. Some very popular items have “smart” part numbers which indicate a 27’ or 30’ strap for example. Our interior van straps also indicate a 12’, 16’, or 20’ for standard assemblies. Doleco USA tie downs or loop straps, for example, can be ordered from us in any length. If we were to create every item in every possible length in our system, it would lead to a confusing number of item numbers and problems for our staff and our customers. However, we have created unique EAN numbers for some standard items with standard lengths. If you need them, just ask for them.

When do tie downs have to be removed from service?

The entire tie down must be inspected before each use and it shall be removed from service if ANY of the following are detected:

- Identification tag is missing or not readable

- Holes, tears, cuts, snags or embedded materials

- Broken or worn stitched in the load bearing splices

- Knots in any part of the webbing

- Acid or alcali burns

- Melting, charring or weld spatters on any part of the webbing

- Excessive abrasive wear or crushed webbing

- Signs of ultraviolet (UV) light degradation

- Distortion, excessive pitting, corrosion or other damage to buckles or end fittings

- Any conditions which cause doubt as to the strength of the tie down

To detect possible damage, perform a visual inspection of the entire length of the tie down. Even damage that looks “minor” can significantly degrade tie down performance. If you have ANY doubts about the condition of a tie down, DO NOT USE IT.